In a Volatile Economy, Purchasing Practices Need to Change

Businesses must change procurement systems - Production efficiencies, rising commodity prices and high price volatility demand a new approach to purchasing for manufacturers.

Three major changes over the past 2 decades have created a need for businesses, and especially manufacturers, to change their procurement systems.

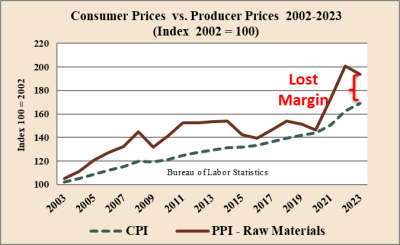

First, the Producer Price Index has increased over 194% since 2002 while the Consumer Price Index has increased less than 170% over the same period. The PPI reflects the prices manufacturers pay for their raw materials. The CPI reflects the prices consumers pay for the products manufacturers produce. This changing price dynamic has squeezed the margins of most manufacturers.

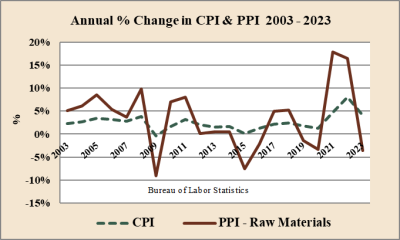

Second, during the same period, the PPI has been much more volatile than the CPI. This creates periods of debilitating gross margin compression for any business that has exposure to raw materials but doesn’t manage it’s pricing to include a real time raw material cost component.

For example, recent large freight cost increases have depressed margins for many manufacturers and distributors. These increases coupled with severe supply chain disruptions are creating double jeopardy for many companies; losing margin to higher costs while also losing sales due to the supply chain disruptions.

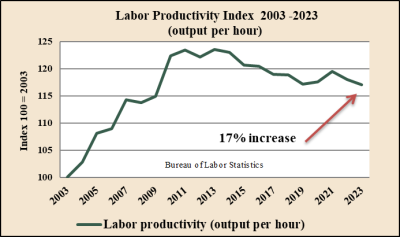

Finally, labor productivity gains have reduced labor cost as measured by output per hour. This reduced the costs of labor as a percentage of total costs, making raw materials and energy an even larger component of the gross margin cost structure.

The bottom line: Productivity gains made by manufacturers over the past 20 years have been offset by higher raw material and energy costs, while profits are much more volatile due to swings in input costs.

In today’s world of more volatile raw material and energy prices, trade wars and global calamities that disrupt supply chains, businesses with exposure to commodity inputs must radically change their procurement model to merge buying and selling systems, develop the best hedging options and manage the gross margin in addition to costs.

Three areas must be developed for businesses to thrive in today’s environment:

1. Implement a Risk Management system that address how to manage price volatile raw material and energy inputs with sales prices that may be difficult to increase. Here are three steps you should have in place:

- analyze the price risk on your key inputs

- define your price risk tolerance for each input

- develop a system to manage the risk within your established tolerance

The risk management system must also address the availability of all inputs included in your supply chain. For more on this topic see CFO Talk - Learning from Crisis. Building a Robust Supply Chain

Exposure or position reporting is also an essential building block to a risk system. Position reports link the units of input bought with the units of output sold. Net exposure, your “long or short” position, is where your price risk lies. Understanding the cost drivers of your inputs and their price volatility will help you establish “position limits” that adhere to your company’s risk tolerance.

Exposure management and quantifying risk tolerance are the foundation for the other two areas essential in changing the procurement model - hedging and margin management.

2. Develop Hedging strategies based on the company’s risk tolerance and define what tools are appropriate to hedge your price risk. This risk can be held internally or passed on to customers, vendors and third parties. Key items to consider while developing hedging tools include administrative complexity, staffing requirements, capital needs and industry sophistication. Hedging tools can be simple, like escalators in a sales contract or minimum/maximum quantities on supply contracts to very complex options strategies or over the counter instruments tailored to very specific risk.

Analyzing your price risk hedging options will provide unique insight into your business. If a risk is difficult or expensive to hedge your focus needs to turn to eliminating units of exposure to that risk.

A tangible benefit to developing an exposure system, risk parameters, hedging strategies and risk mitigation tools is you will improve your procurement skills and buy better.

3. Create a Margin Management system that links the position and price risk for your company’s inputs and outputs. It includes exposure reporting, earnings forecasts and scenario planning. Margin management uses risk management systems and hedging strategies to protect and enhance margins while connecting the procurement, production and sales functions of the company.

Here are some warning signs that will help you identify if your risk and margin management systems need to be revamped:

- Your organization spends more time managing costs than margins.

- Your organization does not have a method to measure the financial impact of price changes on your key inputs.

- Sales decisions are made independent of buying decisions and vice versa.

- “Higher raw material and energy costs” frequently explain away earnings shortfalls.

- Your organization has a separate department called procurement or purchasing.

- “Risk Management” mainly refers to the relationship you have with your insurance broker.

- “Hedging” conjures up the image of expensive, complex transactions that are to be avoided.

Visit the libraries of product pricing expert Mark Stiving and procurement leader Rick Pay for more ideas on improving margins at your company.

To compete in our global economy manufacturers must adapt their risk and margin management system to today’s environment.

Identify your path to CFO success by taking our CFO Readiness Assessmentᵀᴹ.

Become a Member today and get 30% off on-demand courses and tools!

For the most up to date and relevant accounting, finance, treasury and leadership headlines all in one place subscribe to The Balanced Digest.

Follow us on Linkedin!