Stop Using Lean to Cut Costs

Welcome to CFO.University’s transcript version of Andrea Jones’, CFO Ed Talk. Stop Using Lean to Cut Costs. Andrea advises CFO’s to start using Lean to increase revenue, and stop using Lean to cut costs. She provides a clear-cut model and real-life case studies to drive her points home.

Enjoy. Learn. Engage.

———————————————————————————————-

Imagine this scenario, your company didn’t make its earnings last quarter, and you as the CFO have the unenviable task of bringing those numbers to your leadership team. Everyone’s going to start talking and pretty soon someone will come up with the idea that you need to cut costs. Maybe you’ll even decide to use Lean to cut costs in your company. Well, you wouldn’t be alone. A recent headline from CNBC states, Coke goes Lean to cut 1200 jobs as part of an $800 million cost savings plan. Today, so many companies use lean to cut costs, that Lean has become a four-letter word in many organizations.

Several years ago, a company that I worked for would constantly reissue Lean mandates to cut costs and cut jobs. Well, it doesn’t have to be this way. Interestingly, when Jim Womack popularized the term Lean in his 1991 book, The Machine that Changed the World, he was referring to how Toyota would produce products with little to no waste while adding value to the end customer, and revenue for the company.

The DAER Model

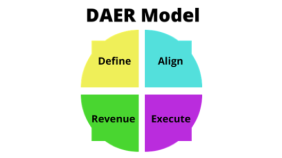

Now, if you’re as profitable as you would like to be, maybe you don’t need to read the rest of this talk. But for the rest of us, there’s a way that you can use Lean to not only cut costs but to increase revenue in your company. This is the DAER model. It stands for Define; define the problem or the issue in your organization that you’re looking to address. Collect some data around that issue to really figure out what’s happening. Then Align your team to that data, make sure that everyone understands the issue and further is aligned also in what they need to do about fixing it. Next, Execute to that plan. And finally, realize the Revenue that comes from your efforts in this area.

Case Study – Debottlenecking the Production Process

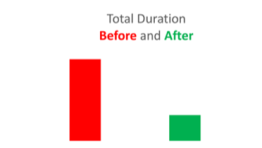

Consider the following case study. A manufacturing company had a stated six week delivery lead time. Well, they weren’t making that lead time and they were concerned. So, when I ask them, what is your actual average lead time? They really didn’t know. So first, we had to collect some data. After we collected this data, we found that their lead time was actually seven weeks, on average, not six. But the interesting thing about the data was that no matter what you say about Lean and touching the product, needing to change the form, fit or function, in order for each touch to be, quote, value-add, they were actually spending 75% of their time in production doing nothing. The product was just sitting there waiting, nothing was actually happening. So, it really didn’t matter what they were doing when they touched it, as you can see, in the green bars on the chart to the right. The red bars signify the 75% of the time that the product was sitting around doing nothing. Well, once we had collected and showed this data to the team, everyone jumped on board and was very aligned to the problem. Then we had to come up with what we were going to do about that. We decided to use a Pull System. A Pull System takes the theoretical constraint of a system, in this case, when the machine would actually produce the product, which is the large green bar toward the end of the chart, and pulls everything in toward that step. So, we didn’t have to do anything ahead of time. We didn’t have to worry about all the other steps. But we would pull things over towards that step. Everybody was aligned to this and we moved ahead towards execution. The way we executed was by adding a buffer, a Kanban in Lean terms, in front of that machine. So, while the machine was running, there would be four pieces of production staged in front of it. Soon as it was done, it would move off, pull the next one on, and everything would move up a spot. An open spot was the indication for the upstream steps to get ready for that piece of equipment. The program was designed to stage the materials and put everything in front of that equipment.

All they did was change their philosophy by pulling things onto the equipment rather than pushing them over in random order, but you can see the staggering results. The chart to the left shows in red, the 35 business days or seven weeks of time that it took them to produce the product before the Pull System was in place. After the Pull System (Kanban) was put in place production time declined to 11 business days, represented by the green bar. So, they removed over three weeks (69%) out of this whole process. And what does that do for their revenue? Well, from a financial perspective, their cash flow is improved because they’re able to invoice sooner. Their inventory turns are up. Their throughput time is down so their throughput itself is up. Machine utilization is up. Equipment capacity is up because again, they took weeks out of the production cycle. On average, they were able to do more in any given year without adding any additional overhead costs.

But the best thing that happened for this company was that now they were able to go to their customers and say, “Hey, would it be a competitive advantage to you if we can deliver in about two weeks rather than the six or more that we were delivering in before?” They were able to increase their sales and therefore their revenue even more.

Now, you might be saying, Well, that’s all great. I’ve heard about Lean manufacturing, it works well in a manufacturing environment. But I’m not in a manufacturing environment. So how can this lean thing work for me?

Case Study – Properly Allocating Resources

Well, consider the case study from a web platform company. This platform company was onboarding about 50 customers a month to its web platform and it moved to 350 in one month when it added a sales channel partner. So, you can imagine that this onboarding process, which was about five steps, was very manual when people were onboarding 50 clients a month and when moving to 350 in one month everybody was super frustrated. They couldn’t get through the process. Work was starting to stack up and no customers were actually on their web platform to even earn revenue in the first place. So, there was a big problem. We really needed to figure out where in that five-step process were the big opportunities. So again, we started to collect some data. In this case, we collected the backlog. So how many customers were waiting at each step? Well, interestingly, in both step 2 and step 4, there were training steps. Now you can see from the chart to the right that step four had a gigantic backlog. But what was the difference? In step two, there was a five to one training ratio. Five customers to one trainer. In step four, that ratio was one to one. Now, it doesn’t take a rocket scientist to know that if you go from a five-lane highway, down to a one lane highway, things are going to get backed up. And that’s exactly what had happened to them. In fact, they had 630 customers waiting at step four, just to get through that process. I calculated that it would take them about six years to get through at the rate at which customers were coming in. Six years is an awfully long time to wait to earn revenue on your web platform business.

So, now that the problem is well defined, you would think that people would jump right on board and be aligned to what to do next. This is an interesting situation though because the manager who had set up that step 4 to be the one to one trainer was actually not bought in. That manager really believed it needed to be one to one training there. So, they didn’t do anything about that right away. Instead, they added some online software to schedule people. So, if someone quit or canceled at the last minute, they could backfill easily. They added training slots for step four. They made sure all of their trainers were cross-trained. That helped some, but it still didn’t address the main bottleneck. They didn’t level load every step in their process. After this went on for a few more months and the problem was just exacerbated. They realized and all became aligned that the problem was in step four and they needed to address it. After that, execution became very straightforward. All they had to do was increase the ratio at step four so that the entire system was matched and level loaded. They were able to get customers on board within a few months and start earning revenue from their online web platform company.

Don’t’ Embrace a Stone Age Excuse

Now, maybe you’re thinking to yourself, hey, that’s great. It would be wonderful to have the time, to really define a problem, to come up with all this data, analyze it and work to get the team on board. Sounds like a terrific idea. But I am just so busy. I’m so busy doing my daily work. I don’t have time to do anything else. Anything else is overwhelming. Too busy to think about this? Well, as you can see from this cartoon, being busy is a pretty convenient excuse that’s been around for a while. So, I dare you. Use the DAER model to consider how you can use Lean to increase revenue in your company. Define the problem. Figure out what’s really happening and use data to really see that and get everyone aligned to the problem and to the data. Align all of your team to what really needs to happen. If you take the time to finish the define and align steps well, the execution becomes relatively straightforward. And don’t forget, realize the revenue that comes from your efforts. Now, if you’re always using Lean to cut costs, well, you’re probably not going to be too popular with your employees. But if you can message Lean in the way in which it was intended, to add value to your customers and revenue to your company. Well, you tell me CFOs, What could be more important than that?

Watch the CFO Ed Talk™or listen to the Podcast Here!

Identify your path to CFO success by taking our CFO Readiness Assessmentᵀᴹ.

Become a Member today and get 30% off on-demand courses and tools!

For the most up to date and relevant accounting, finance, treasury and leadership headlines all in one place subscribe to The Balanced Digest.

Follow us on Linkedin!